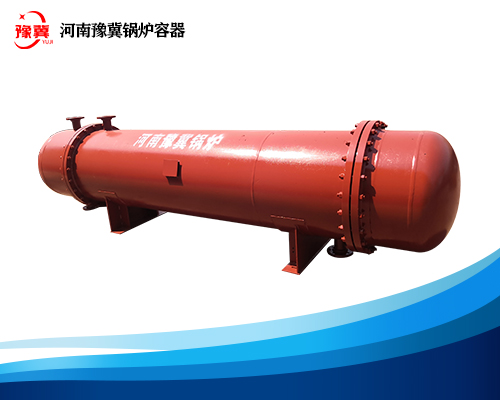

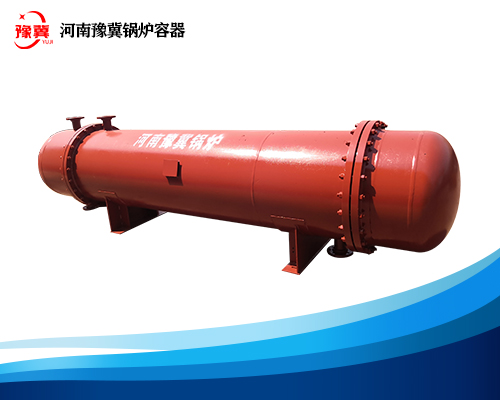

Shell and tube heat exchanger It is an inter wall heat exchanger with the wall of the tube bundle enclosed in the shell as the heat transfer surface. The heat exchanger is simple in structure and reliable in operation. It can be made of various structural materials (mainly metal materials) and can be used under high temperature and pressure. It is a widely used type at present.

Structural performance:

The shell and tube heat exchanger is composed of shell, heat transfer tube bundle, tube plate, baffle plate (baffle), tube box and other components. The shell is mostly cylindrical, with tube bundles installed inside, and both ends of the tube bundle are fixed on the tube plate. There are two kinds of cold and hot fluids for heat exchange, one is flowing in the tube, which is called tube side fluid; The other flow outside the tube is called shell side fluid. In order to improve the heat transfer coefficient of the fluid outside the tube, several baffles are usually installed in the shell. The baffle can increase the velocity of the fluid in the shell side, force the fluid to cross the tube bundle several times according to the specified distance, and enhance the turbulence degree of the fluid. The heat exchange tubes can be arranged in equilateral triangle or square on the tube sheet. The equilateral triangles are arranged compactly, the fluid outside the pipe is turbulent, and the heat transfer coefficient is large; The square arrangement is convenient for cleaning outside the pipe, which is suitable for fluids easy to scale.

1. Energy saving, the heat transfer coefficient of the heat exchanger is 6000-8000W/m2.0C.

2. It is made of stainless steel and has a long service life of more than 20 years.

3. The laminar flow is changed to turbulent flow, which improves the heat transfer efficiency and reduces the thermal resistance.

4. High heat exchange speed, high temperature resistance (400 ℃), high pressure resistance (2.5Mpa).

5. Compact structure, small floor area, light weight, convenient installation, saving civil engineering investment.

6. Flexible design, complete specifications, strong practical pertinence and cost saving.

7. Wide range of application conditions, applicable to large pressure, temperature range and multiple medium heat exchange.

8. Low maintenance cost, easy operation, long cleaning cycle and convenient cleaning.

9. The nano hot film technology is adopted to significantly increase the heat transfer coefficient.

10. The application field is broad, which can be widely used in the fields of thermoelectricity, factories and mines, petrochemical industry, urban central heating, food and medicine, energy electronics, machinery and light industry, etc.