The steam water separator is a place where high-temperature nano filtration is used to filter and remove the liquid droplets entrained in the steam and compressed air systems. A large amount of water containing steam and compressed air enter the separator and move downward in a neutral swirl centrifugal direction. Since the density of gas and liquid are different, if they need to be filtered together, generally speaking, The liquid will be filtered to the filter, and the gas will pass through. And because it is neutral, the gas will still move in the same direction. The liquid left on the filter will be diverted to the bottom of the separator to be condensed and discharged, so as to improve the gas quality to reach 98% of the saturated gas effect. "

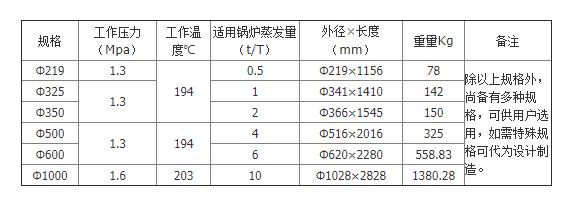

Branch cylinder It is the main supporting equipment of the boiler, which is used to distribute the steam generated during boiler operation to various pipelines, Branch cylinder It is a pressure bearing equipment and a pressure vessel. The main function of the branch cylinder is to distribute steam, so there are several valve seats on the branch cylinder to connect the main steam valve and steam distribution valve of the boiler, so as to distribute the steam in the branch cylinder to the required places. The main pressure components of the branch cylinder are: steam distribution valve seat, main steam valve seat, safety valve seat, drain valve seat, pressure gauge seat, temperature gauge seat; The head, shell and flange are made of Q235-A/B, 20g and 16MnR, and the specification and model are ф 159- ф 1500, working pressure 1-2.5MPa, working temperature: 0~400 ℃, working medium: steam, cold and hot water, compressed air. Special specifications and models can be designed according to user requirements.