DZL biomass hot water boiler adopts a boiler composed of arched tube plates and threaded smoke tubes, which changes the boiler from quasi rigid to quasi elastic structure, eliminates the bracing parts in the tube plate area, reduces the stress, and changes the chimney in the tube plate from two return to single return, which solves the problem of tube plate cracks.

The lower part of the boiler is arranged with a rising exhaust pipe, which eliminates the dead water area at the bottom of the drum, so that the sludge is not easy to deposit, and the high temperature area of the boiler can be well cooled to prevent the lower part of the boiler from bulging.

The university heat transfer threaded smoke pipe is used to obtain the enhanced heat transfer effect, achieve the characteristics of fast temperature rise and pressure rise of the boiler, and improve the thermal efficiency of the boiler.

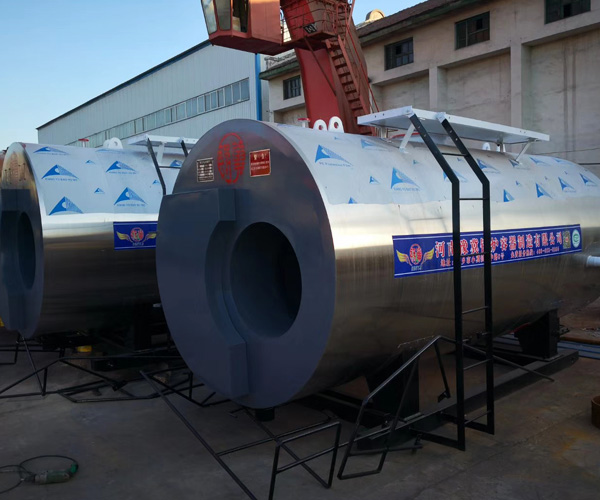

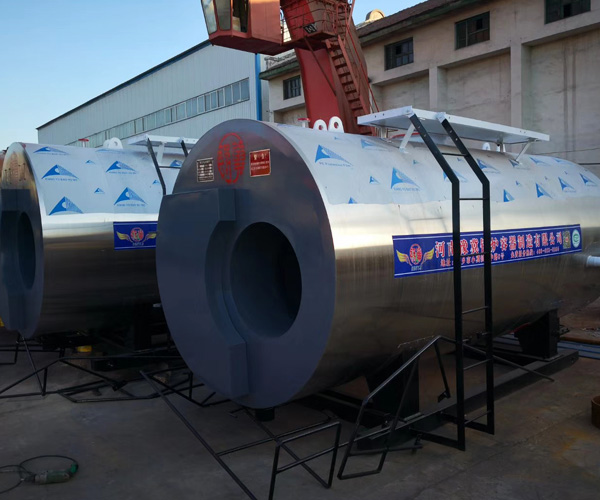

The structure is compact, compared with the same type of boiler, the overall dimension is small, and the basic investment of the boiler room is saved.

Stable operation, convenient adjustment, sufficient output, 110% overload capacity.

DZL biomass hot water boiler has made significant improvements in water circulation. It has successfully adopted the lower header injection technology, eliminated the front downcomer to make the structure simpler, changed the water circulation curve of the riser, and increased the margin of water circulation. The forced circulation hot water boiler uses the pressure head of the circulating water pump to make the water circulate along a certain process in the boiler, so that the water always keeps a high flow rate during operation, reaching a safe water speed to avoid cold boiling, and making the water circulation of the boiler more safe and reliable