Branch cylinder It is the main supporting equipment of the boiler, which is used to distribute the steam generated during the operation of the boiler to each pipeline. The cylinder is a pressure bearing equipment, which is a pressure vessel. Its pressure bearing capacity and capacity should correspond to that of the supporting boiler. The main pressure components of the branch cylinder are: head, shell materials, etc.

The main pressure components of the branch cylinder equipment are: the head, shell and flange materials are Q235-B, 20 # and 16MnR, and the specification and model are ф 159- ф 1500, working pressure 1-2.5MPa, working temperature: 0~400 ℃, working medium: steam, cold and hot water, compressed air. Special specifications and models can be designed according to user requirements.

Branch cylinder The manufacturer told us: product quality assurance. Each sub cylinder is manufactured, inspected and accepted according to national standards. When the sub cylinder leaves the factory, it will be inspected by the local quality and technology supervision bureau after passing the factory inspection. Ensure the safety of cylinder quality, cylinder inspection certificate drawings, etc.

1. Standardized production. whether Branch cylinder Automatic welding process is adopted for the girth seams of products, which is beautiful, safe and reliable.

2. It has complete varieties and wide application scope. The maximum working pressure can reach 16Mpa.

3. Product quality assurance. Each sub cylinder is manufactured, inspected and accepted according to national standards. When the sub cylinder leaves the factory, it will be inspected by the local quality and technology supervision bureau after passing the factory inspection. Ensure that the quality of the sub cylinder is safe. Drawings of cylinder inspection certificate, etc.

4. When the user has special requirements, it can be designed and manufactured according to the needs of the cylinder users.

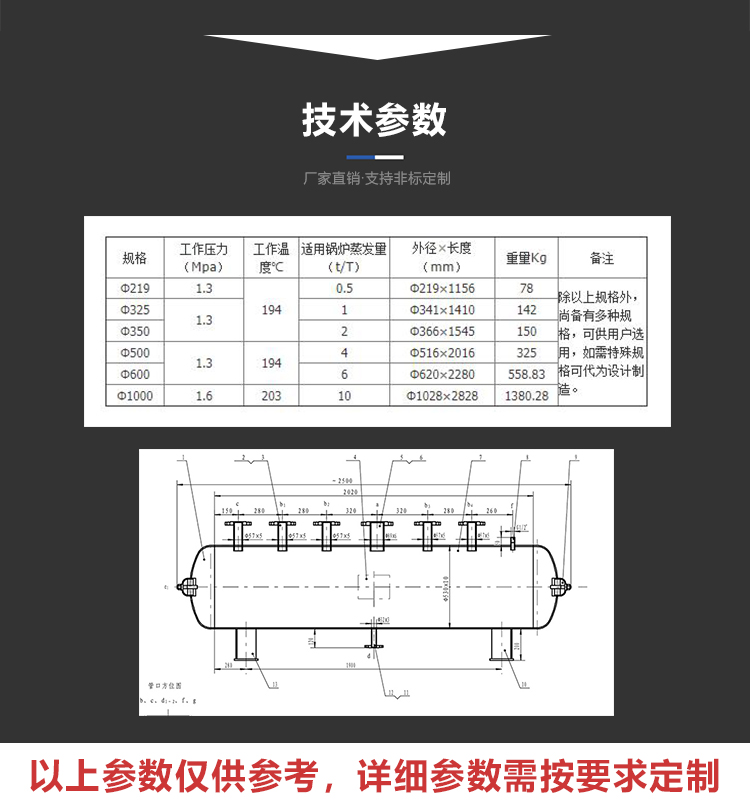

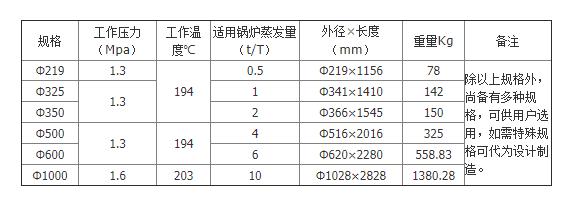

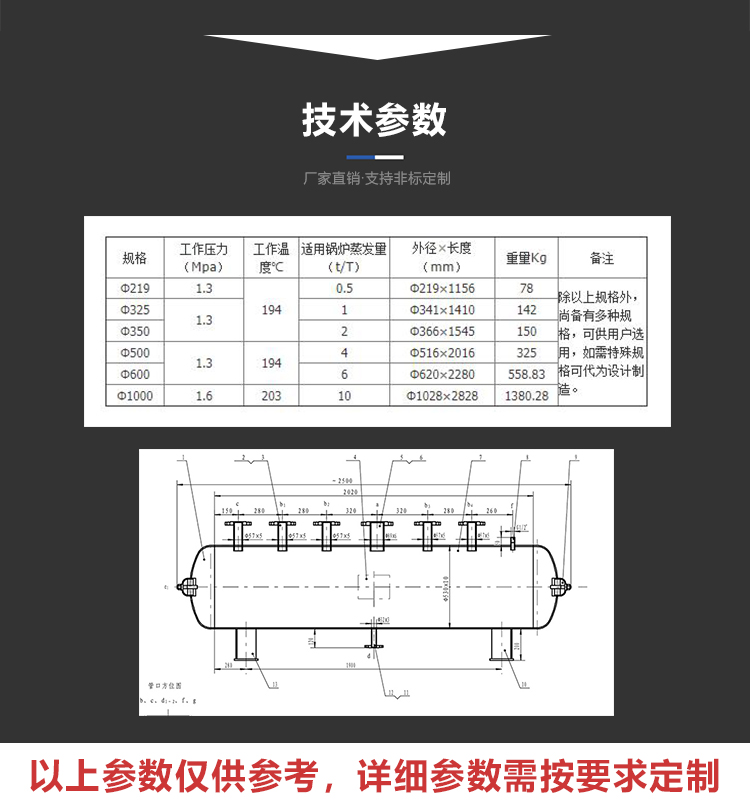

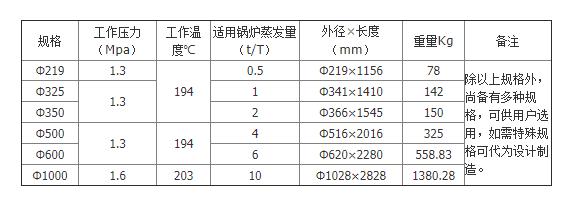

technical specifications

When the medium is steam, it should be designed in accordance with the Pressure Vessel Code, and the cylinder diameter, material and thickness should be determined. General principles: the cylinder diameter should be 2-2.5 times the maximum pipe diameter, which can be determined according to the fluid flow rate in the cylinder. The material should be 10-20 # seamless pipe, Q235B, 20g, 16MnR plate rolled, and the number of connections should be determined by the engineering design.

Ordering Instructions

1. Provide flow, pressure and temperature parameters.

2. Provide the diameter and quantity of inlet, outlet and drain pipes.

3. Yes No Branch cylinder Size required.