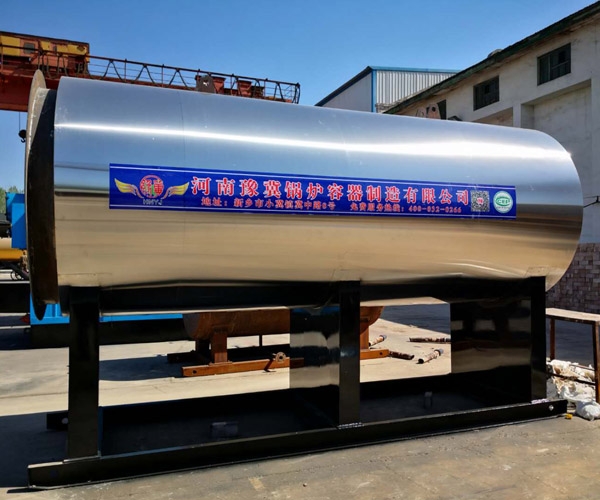

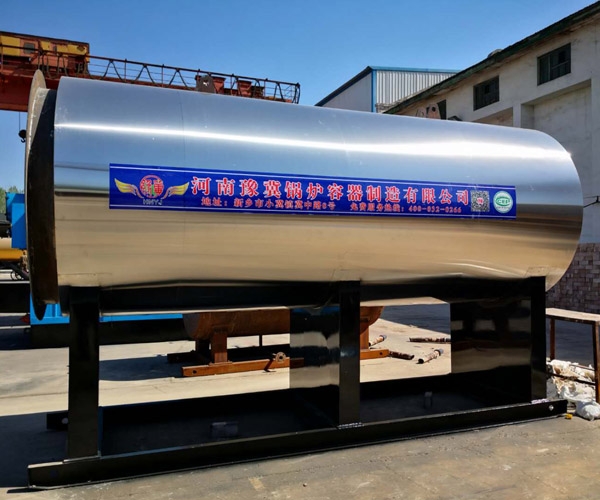

about Hot air boiler In terms of characteristics; Cyclone, semi gasification and oxygen enriched staged combustion technology are adopted; Whole process purification combustion device; Specially designed waste heat recovery structure; Save every penny for customers; It can save 30% - 60% of operating cost compared with oil, gas and electric heating boilers. Vertical+horizontal four return boiler tube combined structure; Suspended combustion mode is adopted; At the same time, hot air is blown for combustion; Large heating area; Fuel combustion is sufficient; High thermal efficiency; The thermal efficiency can reach more than 92% with the economizer. Low-carbon environmental protection; Conform to the requirements of GB13271 for smoke emission; Meet the standard value requirements; Natural oxide; Nearly zero emissions of sulfur dioxide. Stable and reliable; Non pressure operation

Hot air boilers can be used for drying grain. Good hot air boilers play different roles. No matter what refractory materials are used to build hot air boilers, they must be dried before use. It can be seen that hot air boilers play a very important role. How do we configure hot air boilers?

The effective size of the door of the hot air boiler should be 40 * 50mm. The distance between the center of furnace door and furnace bed is generally 90~100mm. An observation door shall be set above the furnace door so that the operator can directly observe the combustion gap in the furnace in the control room and adjust the coal feeding and air blowing volume in time.

In order to monitor the temperature of hot air entering the hot air boiler at all times, a thermocouple shall be installed at the feed inlet, and the temperature measurement range is 0~10 ℃. When Hot air boiler During the downstream drying operation, the feed inlet shall be located on the top of the hot blast furnace, and the outlet position shall be determined according to the transportation direction of dry materials. The door frame of the hot blast furnace shall be placed on the concrete beam of the brick wall outside the furnace.