Plate heat exchanger With its good structure and heating effect, it has become the heat exchange equipment often used in many heat exchangers. Do you know what the structure and principle of plate heat exchanger are?

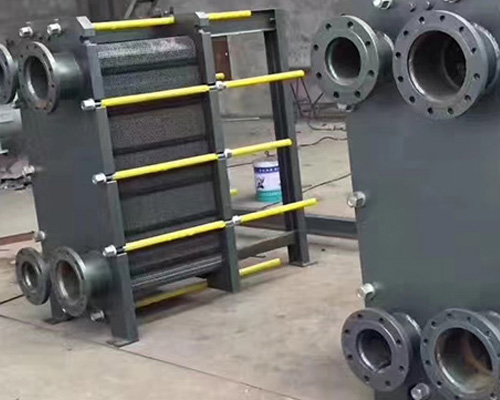

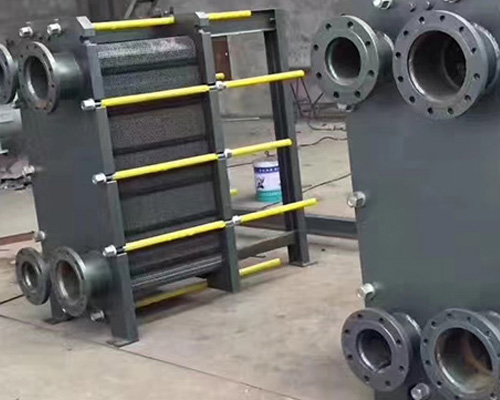

Plate heat exchanger is composed of upper and lower guide beams, fixed pressing plates, movable pressing plates, pipe interfaces, heat exchange plates, plate seals, compression bolts and other parts.

The heat exchange plates shall be assembled according to the process flow, and the sealing parts are stuck around the fixed pressure plate and the movable pressure plate holes. During assembly, the side of the heat exchange plate with the sealing element is facing the movable pressing plate, and the alternately combined plate groups form the fluid channels on both the cold and hot sides. The channel is connected with the corresponding medium through the external pipeline interface to realize the heat transfer of the two media and meet the predetermined overflow control requirements.

The heat transfer plate is the core part of the heat exchanger. The forming process and material characteristics of the plate will have a direct impact on the sealing and heat transfer efficiency. The heat exchanger usually uses water as the cooling medium. The plates are mostly made of stainless steel sheets. Corrugated flow tips are pressed on the plates. The space between two adjacent plates is the medium flow channel. When cold and hot fluids flow on both sides of the plates, heat is exchanged through the plates.

Plate heat exchanger Necessary disassembly inspection, cleaning, pressure test, etc. shall be carried out after using for a period of 1 to 2 years (depending on the actual use conditions). The plates with problems such as deformation or perforation need to be replaced in a timely manner. During this process, the assembly of cooling plates needs to be arranged strictly according to the flow chart. The flow chart is designed according to the cooling process. The plates are connected in parallel or in series. The common ones are single process and double process (or multi process combination) heat exchangers. The medium connection and outlet nozzles of single process heat exchangers are usually fixed on one side of the platen, and the hot and cold media are respectively arranged on one side of the vertical axis of the fixed platen, The same media is on the left or on the right at the same time.